Inhouse Plastics Recycling

With our compact solution combining primary shredder and granulator, it has never been so easy to make plastic waste, defective products or off-cuts ready to re-enter the production cycle. Enjoy maximum productivity with our highly efficient, robust and low-maintenance components.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Processing Waste From Plastics Production

Plastics and other production waste are important raw materials in the manufacturing of plastic products. Lindner shredders were developed with precisely these requirements in mind. Thanks to an adjustable cutting gap and variable screens, you can customise the particle size to the needs of your subsequent processes.

In-house material characteristics

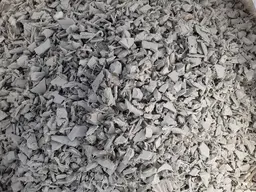

| Particle size | < 10 mm |

|---|---|

| Throughput | > 4 t/h |

| Material | PP, PE, PE-HD, PE-LD, PE-LLD, etc. |

Our primary shredders are resistant to foreign objects and are able to shred hard, rigid plastics to a particle size of <10 mm, as is necessary for recycling purposes. Since the material is often bulky and slightly contaminated, it is not possible to feed the material directly into the granulator. That’s were the primary shredder comes in, splitting the materials to protect the granulator or extruder and minimise the costs of downtime.

INPUT & OUTPUT MATERIALS