ULTIMATELY VERSATILE.

UNIVERSAL GENIUS MEETS EFFICIENCY.

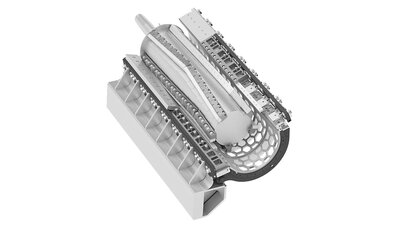

The Merak is the new star in the Lindner product family and sets new standards in terms of versatility, productivity and throughput. The innovative cutting system enables the shredder to be used universally, from coarse primary shredding to universal and secondary shredding, achieving output sizes ranging from 30 to 350 mm. The sophisticated drive concept with three transmission ratios (55 and 87 rpm) enables the shredding of a wide range of materials at the optimum operating point, ensuring increased efficiency.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Lindner Advantages

Key Features

- Mobile, powerful and compact single-shaft shredder with wet-running safety clutch

- 100% electric drive for maximum energy efficiency

- Three different cutting units for maximum flexibility

- Maximum material diversity for a variety of applications

- Homogeneous, defined output sizes from 30 to 350 mm

- High ease of maintenance and servicing

ALWAYS THE RIGHT CHOICE.

Whether primary, universal or secondary shredding - the Lindner modular system with its different drive and cutting units combines a wide range of applications with an unrivalled variety of materials - always at the optimum operating point. Equipped with a torque-controlled safety clutch, downtimes are minimised, protecting both the cutting unit and drive components. The optionally available automatic belt tensioning system (ATB) also makes sure that the power is optimally transmitted at all times.

MERAK PRIMARY SHREDDING

The Merak primary shredding cutting system is specially designed for volume reduction and high throughputs and prepares materials optimally for downstream processes.

Paticel size: 250 - 350 mm

MERAK UNIVERSAL SHREDDING

The Merak universal cutting system was developed for primary shredding as well as for one-step processing of a wide variety of material streams to a defined output size. The closely arranged rows of knives in combination with adjustable speeds ensure high throughput, efficiency and capacity to shred diverse materials and allow for different applications, in each case depending on the requirements and screen diameter. Both the knives and the knife holders are screwable, so that the individual components can be replaced quickly and easily if necessary.

Particel size: 80 - 300 mm

MERAK SECONDARY SHREDDING

The Merak secondary shredding cutting system is specially designed for small output sizes from 30 to 120 mm. Depending on the application and screen size, this cutting unit is ideal for the secondary shredding of waste wood or the processing of industrial and commercial waste into medium-calorific substitute fuel and to fuel calciners.

Particle size: 30 - 120 mm