Razor-sharp efficiency.

High availability meets efficiency

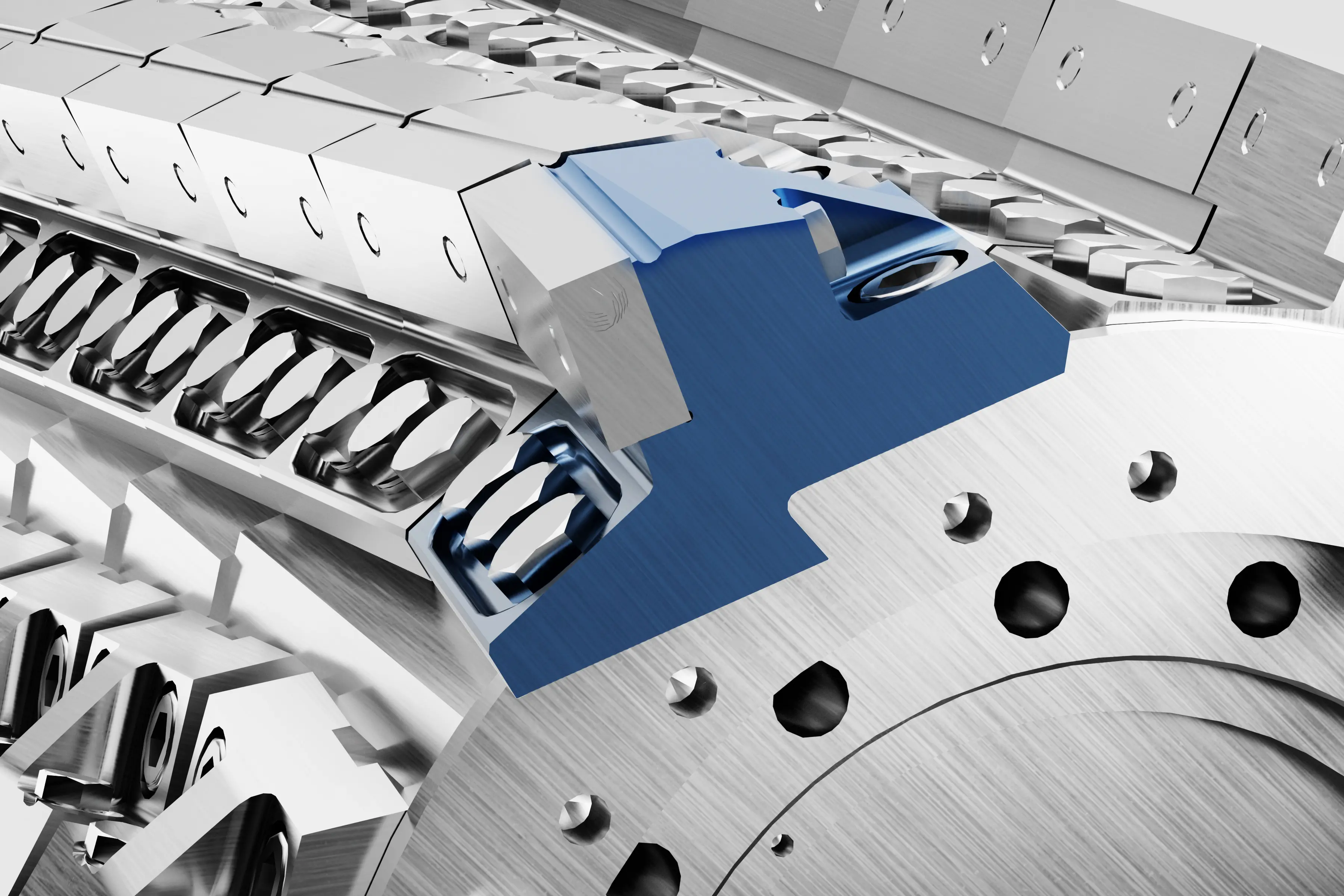

The sophisticated knife holder concept for the Komet and Komet-HP shredder series is setting new standards in terms of operating efficiency. Should a knife holder get deformed due to non-shreddables/contaminants, the damaged knife holder can be replaced in just a few minutes – without any actual welding needed. What‘s more, the new knife holder concept is available with immediate effect, ensuring that you can upgrade your machines without any delay. It can be retrofitted to Komet and Komet-HP used machines as part of maintenance or general reconditioning.

Optimum fit & cutting geometry

Screwing instead of welding – this is the motto of the new knife holder concept of the Komet series, which enables a knife holder to be replaced in just 15 minutes. The result: reduced maintenance and storage costs, shorter downtimes and significantly improved overall efficiency. The unique mounting of the knife holders on the rotor also ensures an optimum fit, maximum stability and retention of the original cutting geometry.

Reduced Downtime.

Rotor Reconditioning

As part of a general reconditioning, it is possible to seamlessly replace the standard Komet rotor with the new Komet rotor model with screw-on knife holders, even on used machines. This adaptability ensures shorter maintenance times and lower costs for the next reconditioning.

- Refitting of the rotor in 3 working days only

- Work can be carried out by in-house staff

- On request, a Lindner service technician can be called in to provide expert support

Maintenance

The screw-on knife holder concept also reduces maintenance costs and minimises downtime. Instead of time-consuming welding and fire protection tasks, which can take up to 4 hours, knife holders can be replaced in just 15 minutes.

- Low storage costs due to only two different knife holder elements

- Shift can be completed - followed by knife holder replacement in just 15 minutes

- No trained personnel required (no welding technician)

- No fire hazard due to the lack of flying sparks during welding (fire protection)

High-precision insertion & optimum geometry

The unique mounting of the knife holders on the rotor also ensures an optimum fit, maximum stability and retention of the original cutting geometry.

- High-precision insertion and, therefore, optimum cutting geometry

- Perfect fit and stability of the knife holder thanks to unique geometry on the rotor

- Eliminates the risk of fitting mix-ups

Low storage costs thanks to the sophisticated knife holder concept

(only two knife holder elements for the entire rotor)

RETROFIT-CHECK

The screw-on knife holder concept can be retrofitted to all used machines in the Komet and Komet-HP series. Our service department will be happy to provide you with detailed information. Let's get in touch!