Service &

Maintenance

Our all-in-one service solutions

To operate your systems reliably while ensuring optimum performance, superior services are a must. We have perfected the art of servicing to give you just that with our new maintenance contracts. Optimum output and correct maintenance go hand in hand for every shredder. Train your staff with our regularly updated Lindner training programmes. Benefit from our original Lindner wear parts to maximise the performance and life of your system. In a nutshell: maximum output and longer life cycles for your wear parts.

The Lindner Service Hubs

We are here for you whenever you need support

Do you have a service request regarding one of our shredders or system solutions. Contact us at one of our service hubs - we are here for you. In case of an emergency, our international service line is happy to help. Please be aware that we provide this service in English only. When calling, please provide us with your name, company, machine type, serial number and number of operating hours - and you are all set.

Monday to Friday, 8 a.m. to 5 p.m. (UTC+1)

Monday to Friday, 8 a.m. to 4 p.m. (UTC+1)

Monday to Friday, 8 a.m. to 5 p.m. (UTC -4)

Monday to Friday 8 a.m. to 5 p.m (UTC+8)

Available outside regular office hours

Lindner Nexus

The Service Plattform that connects.

Real-time machine data, performance monitoring & maintenance.

With Nexus, the new Lindner service platform, you get an overview of all relevant machine data. Real-time data is transferred to the digital platform and summarized in customizable reports, offering optimization potential, custom checklists, and more. Nexus also provides all documentation relevant to the system or individual shredders. The Lindner service and support team can also be reached via Nexus, even 24/7 in urgent cases.

Maintenance contracts for stationary systems

The maintenance intervals depend on the operating hours of your system.

Our maintenance contract includes the following services:

- regular check-ups of your system

- exchange of worn parts

- software updates

- refresher courses for operating staff

Maintenance contracts for mobile machines

This service package includes maintenance of the engine and hydraulics every 500 operating hours or according to the Lindner maintenance schedule. In this way, the mobile shredders always work optimally and unplanned machine downtimes can be avoided.

- periodical check-ups of your system

- exchange of worn components

- software updates

- refresher courses for operating staff

With the "Urraco shaft refurbishment" service package, we also offer shaft replacement and professional analysis of the cutting unit by a Lindner service technician. In this way, necessary service work can be scheduled in good time and the optimum performance of the shredder can be ensured.

Machine check & revisions

Regular inspections of your shredder availability can be maximized and at the same time the risk of unplanned downtime is minimized. Our service technicians analyze the condition of the machine and, based on a detailed report, a recommendation for action is issued.

The Lindner Machine Check Service covers all the service technician hours required to inspect the necessary to inspect the shredder are covered.

- maximum machine availability

- detailed actual condition report

- cost transparency and predictability

Retrofit kits

The Lindner retrofit packages offer the opportunity to modernize existing machines quickly and cost-effectively. They increase performance, improve machine productivity and efficiency and can help to reduce costs. Our retrofit packages are an effective solution for bringing your machines up to date and extending their service life.

Please contact us for more information. Our specially trained staff will be happy to advise you.

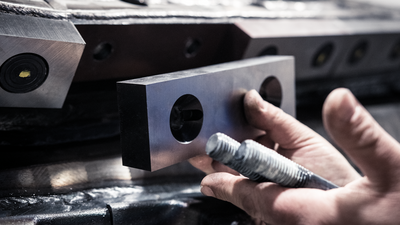

Original wear and spare parts

Only original spare and wear parts from Lindner ensure that the shredders work in a fully optimized manner. With the Lindner wear parts package, customized for your needs, it is possible to optimize the lifetime of your shredder combined with the highest possible throughput.

Ordering Spare & Wear Parts

To ensure your order is processed properly, please provide us with the following machine data:

- machine type

- serial number

- number of operating hours

Short Delivery Times and Maximum Availability

We always keep a large amount of stock available for our clients to significantly shorten delivery times for wear and spare parts.

Staff training courses

Train your staff to maximise your system’s output and the wear parts’ life.

Our Lindner training programme includes:

- specialised training courses tailored to your needs

- in-house or

- directly on-site

We will prepare your staff perfectly to enable them to operate the machine successfully. Having well-trained staff is your guarantee for a smoothly operating system.

Want to know more about the course contents and timings? Our staff will be happy to help.