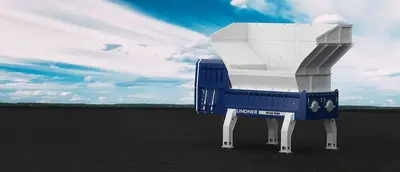

Specialists, get ready: Lindner believes in the future of electric drives in shredder technology and has identified a clear trend in solid recovered fuels production. At IFAT 2018, that took place in Munich from May 14th to 18th, the technology leader with 70 years of engineering expertise introduced the Lindner Atlas. This stationary ‘ripping’ twin-shaft primary shredder perfectly complements the tried-and-tested Jupiter series: the newly developed ripping system ensures very high throughputs and little downtime: it is (cost)-efficient, energy saving, environmentally friendly and produces little noise.

Optical sorting systems, such as those following primary shredders in modern SRF lines, can sort out recyclables more effectively and thus better comply with legal regulations and requirements if the discharge conveyor is evenly filled with material. Furthermore, coarser particles are often an advantage. Film, for example, should be the size of an A4 sheet.

In response to greater demands on recycling sorting processes and the growing need for coarser output in SRF production, Linder has developed the Atlas: the ideal primary shredder complemented by the outstanding secondary shredders of the Komet series.

Shredding with intelligent energy management – the perfect output

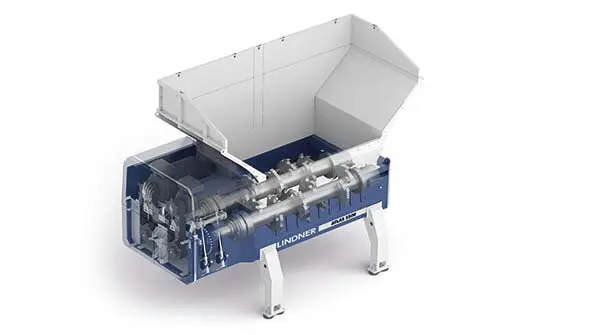

With the new Atlas twin-shaft shredder (a slow-speed, high torque solution), both shafts of the shredding unit can rotate independently while featuring a particularly sturdy frame: perfect for asynchronous and synchronous operation. If one of the two shafts stops due to foreign objects, bulky or tough input materials, the second shaft can still be used in asynchronous operation, ensuring continuous and uniform material discharge. As Lindner Product Manager Stefan Scheiflinger-Ehrenwerth explains, shredding takes place in both directions, enabling a peak throughput of 40 to 50 metric tonnes per hour depending on the input material – even in reverse mode. The robust machine also does not require a pusher/ram: the shafts powerfully pull in material.

Optical sorting systems can then recognise and separate significantly more recyclables from the coarsely pre-shredded, evenly discharged material and take it out of the material flow. The Atlas provides the perfect output for sorting technologies and thus the best possible dosage for secondary shredding.

What makes the Atlas shredder so unique and innovative – asynchronous, ripping shaft systems have long been available on the market – is the machine’s electric drive concept. Lindner, as a leader in shredding technology, further developed its well-established asynchronous motor belt drive and is now introducing a first: a twin-shaft shredder with intelligent energy management. Stefan Scheiflinger-Ehrenwerth enthuses when describing the company’s latest development: ‘As a result, the machine consumes up to 40% less energy than shredders with conventional hydraulic drives and has even faster reaction times.’ What is more, a container for the oil tank is no longer required: ‘A hydraulic power pack as large as the machine itself is no longer needed.’ Compactly built, the Atlas takes up little space in the client’s facilities.

Independent and virtually maintenance-free

Although hydraulic drives have the advantage of allowing the pressure to be altered quickly, they also generate a lot of heat. The energy loss is therefore considerable and hydraulic fluids might also escape. Additionally, oil must be refilled regularly and the engine serviced periodically. An electric drive does away with all of these tasks, and produces far less noise than a hydraulic system.

The Atlas is thus very quiet and virtually maintenance-free. ‘Apart from the regular maintenance intervals with the obligatory hard facing after a certain number of operating hours, virtually zero maintenance is required,” says Stefan Scheiflinger-Ehrenwerth. ‘No cutting gap needs to be readjusted, the machine simply operates up to the next scheduled maintenance.’ Lindner has developed an independent system that is designed for continuous operation – 24 hours a day, 7 days a week. ‘The Atlas stands for maximum productivity without downtimes,’ summarises Stefan Scheiflinger-Ehrenwerth. ‘You power up the machine on Monday morning and let it run all week long.’

The Atlas features a torque-limiting safety clutch, which protects the drive unit from damage in the event of blockages caused by non-shreddables. When developing its stationary primary shredder, Lindner considered it vital that tried-and-tested technology was reflected in innovation. Another key example are the proven robust sensors, which ensure a controlled machine shutdown and therefore protection for all components. The shredder is conveniently controlled by remote control from the loading vehicle (wheel loader, excavator) or the control room.