The Austrian specialist in shredding technology and system solutions for waste processing invited guests to the Lindner Atlas Day on the scenic Lake Wörthersee on 1 October 2019 to present the eponymous next generation twin-shaft primary shredder for automated 24/7 operation.

Observing this colourful group of more than 120 people leaving their hotel on Tuesday morning, one might think they were an illustrious travel group. The fact that these visitors from all over the world, including countries such as Brazil, Morocco, Russia, China and Japan, actually belong to the who’s who of the international recycling industry only becomes clear when one listens more closely. They’re talking about recycling rates, valuable recyclables, waste streams and efficient processing technology. But the day’s hot topic is ideal sortability and the primary shredding of waste that’s necessary to make it possible.

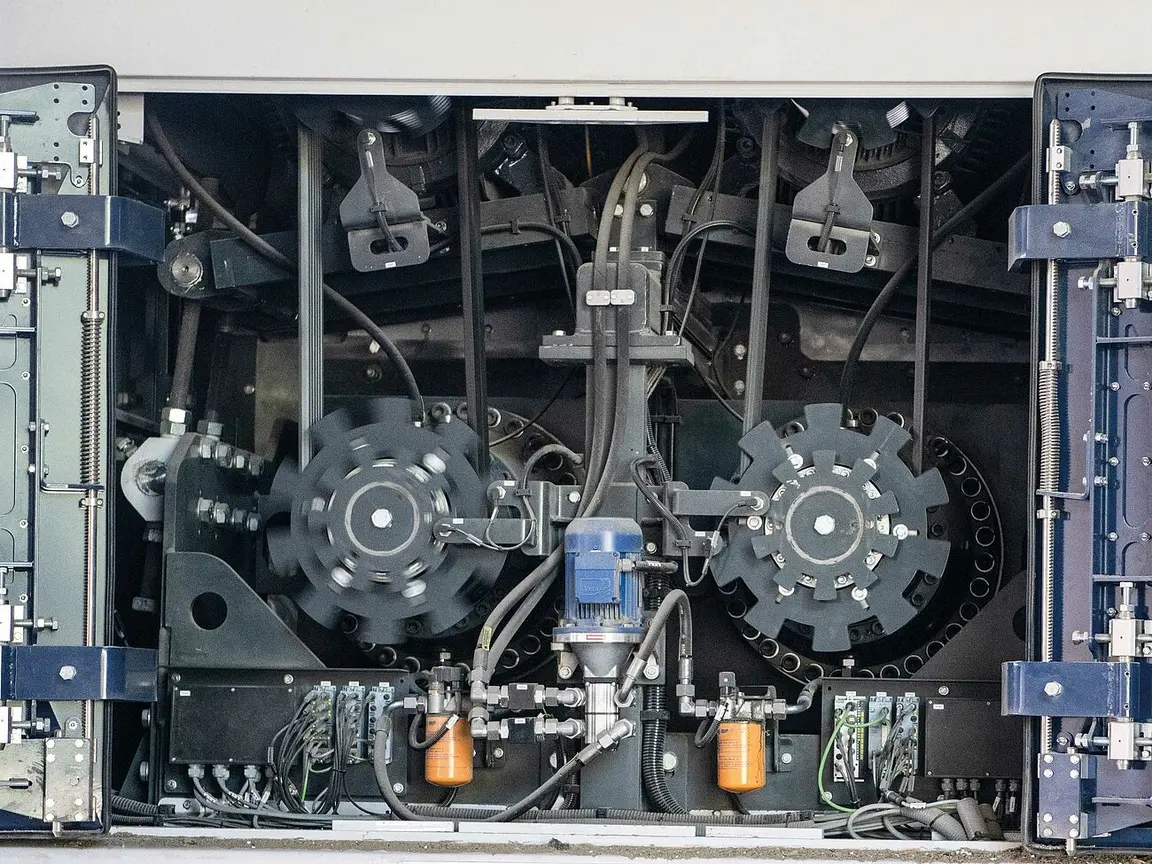

‘At the moment, everything is heading towards a circular economy. Our diverse, international audience is proof that this trend is not only emerging in Europe, but all over the globe. In addition to the steadily increased recycling rates set by the EU, the 180 countries adhering to the Basel Convention, which governs the export and disposal of hazardous waste, have also decided to include plastic in the list of waste requiring “special consideration”,’ explains Stefan Scheiflinger-Ehrenwerth, Head of Product Management at Lindner Recyclingtech. These developments call for new technologies that will make it possible to cope with the ever-growing amounts of waste and to process them efficiently. To achieve this goal, Lindner’s design team focused on successfully combining the following three aspects in the Atlas shredder: ideal output size and chunkiness for subsequent sorting processes with high energy efficiency and 24/7 operation.

24/7 operation combined with minimum downtimes

New to the latest Atlas generation is the FX fast exchange system. For maintenance with minimum downtime, the entire cutting system can be completely exchanged in under an hour. Thanks to a second cutting unit, made up of a shaft pair and cutting table, it’s possible to keep up production while, for example, welding work is carried out on the rippers.