Powerful Efficiency.

Powerful performance, no compromises.

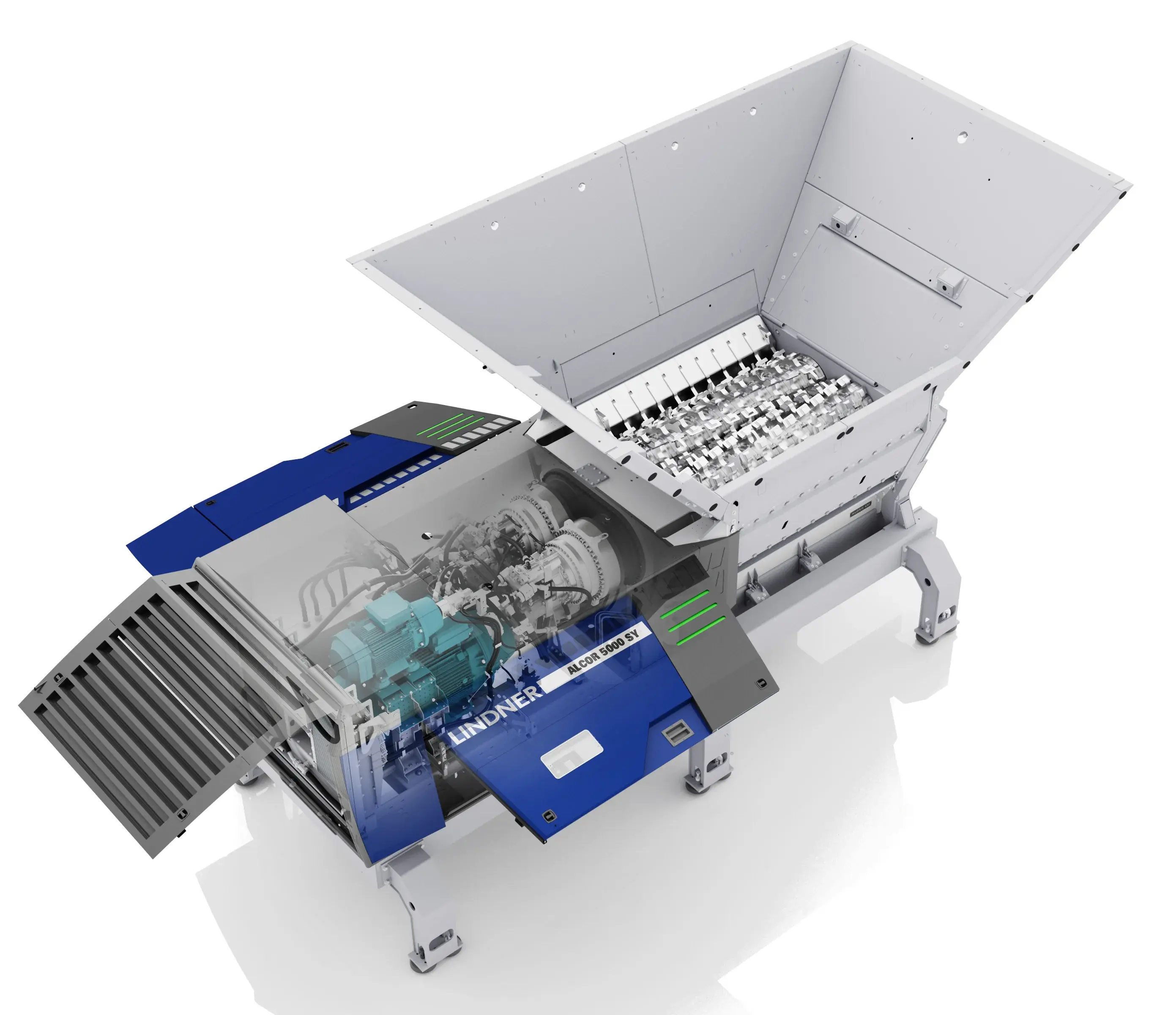

Alcor, the new twin-shaft shredder from Lindner, presents itself with the usual high throughput, powerful efficiency and, for the first time, stationary. The 355 kW electro-hydrostatic drive impresses with its fast response to load changes and due to its high torque is also suitable for particularly tough materials. The Lindner Sky Flap enables easy access to the cutting unit, allowing contaminants to be removed quickly. The breaker bar can also be easily removed or replaced via the Sky Flap. Thanks to the use of different shaft types, the Alcor can be used to efficiently shred a wide range of materials - from waste wood, rootstocks, C&I and MSW to aluminium and mixed scrap.

Connect With Us

Need answers about applications or particle sizes? Reach out today - our specialists are ready to provide support. Together, we'll uncover your perfect solution.

Input & Output Materials

Lindner Advantages

ALCOR 5000 SY CUTTING SYSTEM

The cutting system of the Alcore consists of two synchronously running, fully welded rotors. The synchronous ripping (ripping apart, ripping up) at low speeds with high torque combined with the dynamic energy recovery enables:

- Synchronous twin-shaft cutting system

- Two shaft types: SF (fine) and SR (rough)

- Perfect for waste wood, C&I, MSW, metal scrap

HIGHLY EFFICIENT ELECTRO-HYDROSTATIC DRIVE WITH TORQUE RESERVES

ELECTRO-HYDROSTATIC DRIVE FOR:

- High torque

- High effectiveness

- Quick change of shaft direction

- High energy efficiency