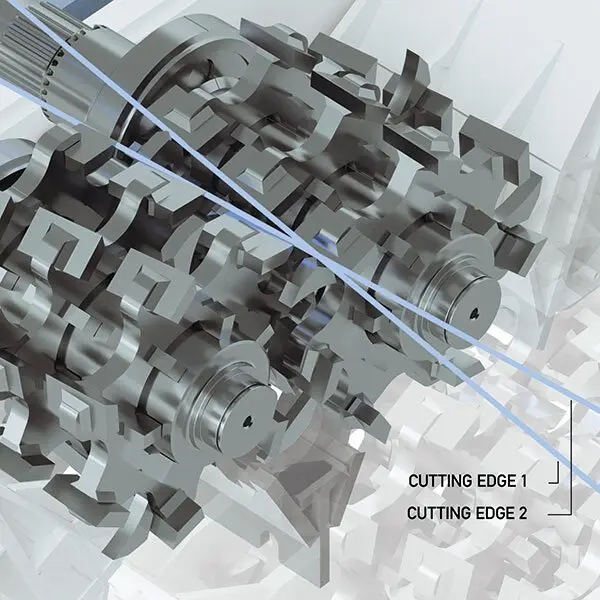

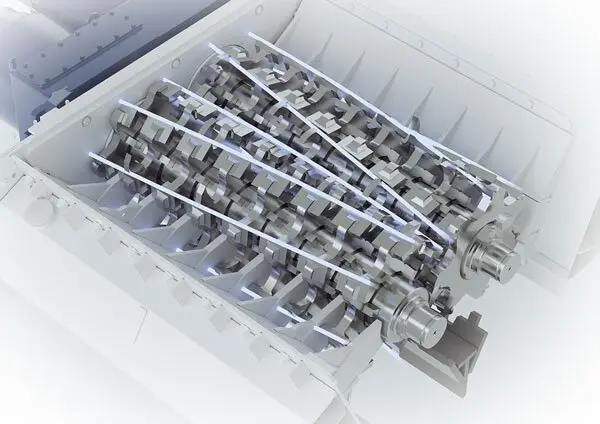

Spittal an der Drau/Austria, January 2021. The way a twin-shaft shredding unit works is fairly simple: two tools moving in opposite directions draw in the collected waste material for shredding and crush it all together into smaller pieces. If it is purely about volume reduction, for example for easier transport, this can be achieved with conventionally designed shafts. Some applications, however, require specific particle sizes for their processes.

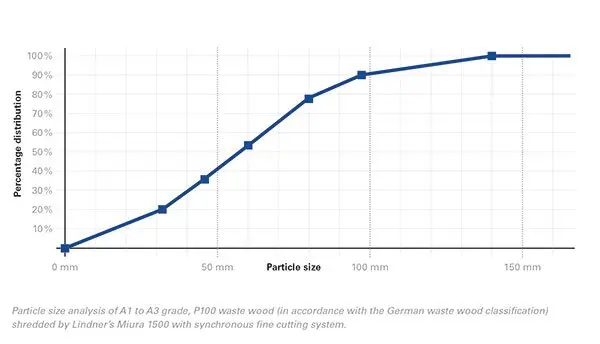

Plants that recover energy from waste wood, for example, are usually designed with a standardised particle size in mind. Oversized particles in the material stream can block the conveyors or safety systems such as rotary valves. In addition, too many fines negatively affect combustion and very small particles might lead to lumps jamming the facility. Therefore, if the required size is not obtained in the first shredding step, the material must be treated further. The crux of the matter is that additional processing is costly, reduces the recycler’s profit margins and, in the worst case, leads to customer complaints. To avoid these problems, Lindner’s patented SF synchronous fine cutting system is specifically designed based on the following two simple principles.